Trusted by

Bearing rings and fatigue

- Roller and ball bearing ring blanks in Vibenite® 281

- Extreme rolling fatigue resistance

- Short blank delivery time, 5-10 days.

- Hardness 67 HRC

- Patented alloy

- Patented heat treatment

- Proprietary melting settings

Separation details high erosive wear

- Separation rings in Vibenite® 280

- Extreme erosive particle resistance

- >10 times lifetime

- Hardness 70+ HRC

- Patented alloy

- Patented heat treatment

- Proprietary melting settings

- Optimised 3D design, instead of stacked and riveted sheet plates

Food cutting

- Cheeze doodle knives in Vibenite® 350

- 5-10 times increased life time

- Hardness: 60 HRC

- Patented alloy

- Patented heat treatment

- Proprietary melting settings

Metal sheet stamping

- Punch and die made of Vibenite® 150

- Stamping of high performance steel

- Performance: increased from 50 000 to 70 000 cuts

- Price: reduced by 50% (from ~ €5000/pair)

- Improved performance and lower price vs a special

- PM stamping material

- Hardness 62 HRC

- Patented alloy

- Proprietary melting settings

- Unique way of 3D-melting used

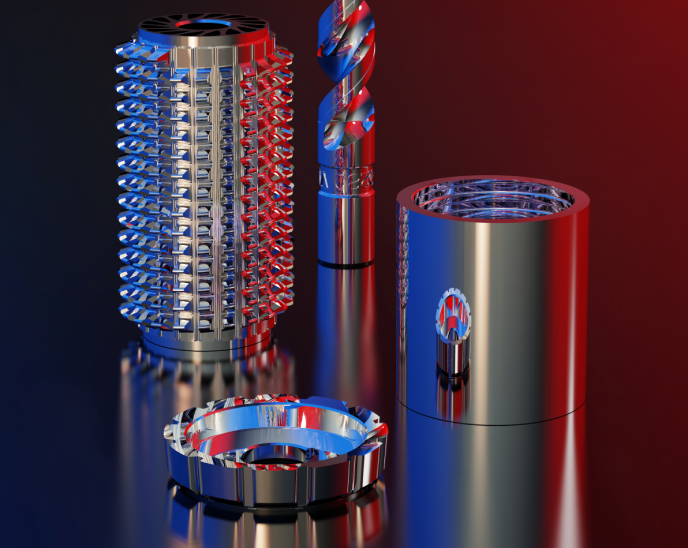

Metal cutting tools

- Automotive metal cutting tools in Vibenite® 290

- Hardness 76 HRC

- Excellent cutting performance (>10 times lifetime)

- Patented alloy

- Patented heat treatment

- Proprietary melting settings

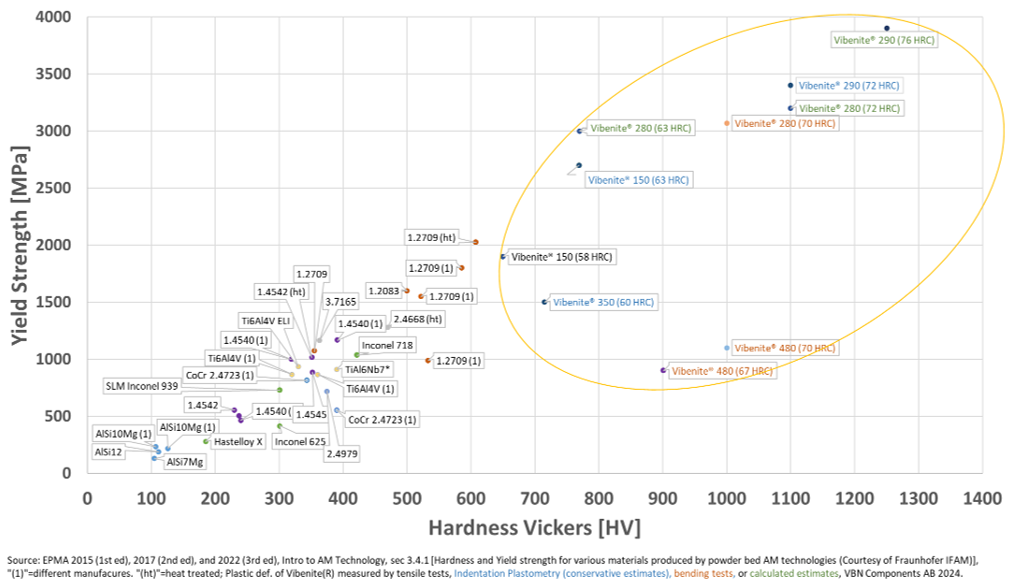

Vibenite® v/s other AM materials

Management

Contact

info@vbncomponents.com

+46 (0)760 07 79 72

VBN Components AB

Verkstadsgatan 8

SE-753 23 Uppsala

Sweden

VAT: SE 556791573001

Reg. nr: 556791-5730

Magnus Bergman

CEO

Ulf Melin

Chairman